Claudia Calder discusses the what, why, and how of using personal protective equipment and respiratory protective equipment to protect against COVID-19.

With the outbreak of COVID-19, there has been a lot of talk about PPE (Personal Protective Equipment) and RPE (Respiratory Protective Equipment). In this article, I explain what these are, why they are used, and how to wear and dispose of it properly.

This guidance can be used as part of your Prevent strategy, under the Prepare, Inform, Prevent, Recovery approach to returning to work. Read more about it the approach at the link.

Before we explain what PPE or RPE is and why it is needed to protect ourselves against COVID-19, we need to understand where it fits in with overall safety control measures.

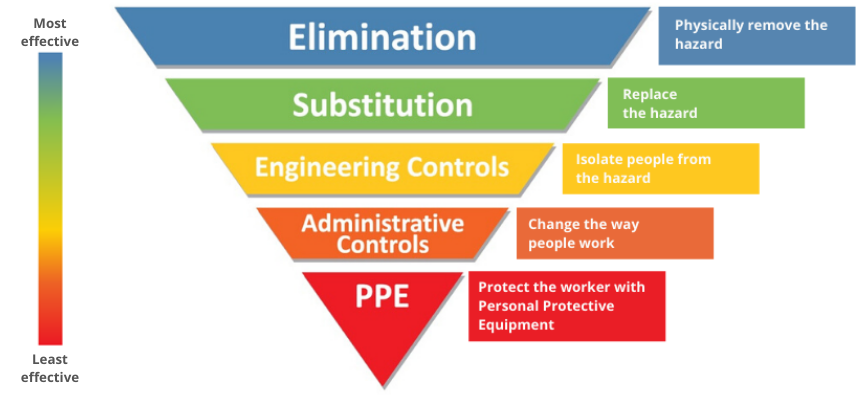

Hierarchy of Controls

Safety experts use a system called “Hierarchy of Controls” to eliminate or minimize exposure to hazards, which ranks the effectiveness and efficiency of hazard controls.

Simply put, it is a system where you start at the top of the hierarchy and try to put in the appropriate control measures at each stage until you have eliminated or minimized the risk as much as possible.

Elimination – Physically Remove the Hazard

To eliminate COVID-19 in the population, the virus needs to ‘go away’. To do this, a vaccine needs to be developed and administered to the population, so that we are protected from developing the disease from the virus.

There is no way of ‘killing’ the virus all at once unless somebody develops an airborne neutralizing anti-viral vector, which is currently impossible to do. Sadly, we don’t live in the movies!

Substitution – Replace the Hazard

We cannot substitute COVID-19 for something else; however, when cleaning our hands, we can substitute alcohol-based sanitizer (which can cause dermatitis) for soap and water.

Engineering Controls – Isolate people from the hazards

This is the stage where we can start minimizing the risk against COVID-19 in the workplace. COVID-19 is transmitted person-to-person through respiratory droplets from coughs and sneezes and possibly breath.

Physical engineering controls such as plastic screens have been put in place in shops to protect customer service staff from customers, as well as physical distancing measures. Office environments have also put screens in between workstations to minimize the risk of transmission between workers.

At this stage, we have slightly reduced the risk to the transmission, under certain working environments. So, what can we do next to reduce the risk even further?

Administrative Controls – Change the Way People Work

Administrative controls include training, procedure, policy, or shift designs that reduce the risk of a hazard to an individual, typically changing the behavior of people rather than removing the hazard.

As we start to return to work, whether it be in an office or factory or shop, workers are going need to change their behavior to include washing hands (good hygiene practices) and physical distancing.

This already started to become ‘normal’ but these messages will need to be reinforced in the workplace, as we will forget to do these things. We need to recognize that our environment sometimes directs our actions. For example, last time we were in the office, we chatted in the kitchen and just got into the lift with whomever. In the COVID-19 world, we just won’t be able to do this without thinking of the potential consequences.

Your return to work/COVID-19 risk assessment will layout what control measures will need to be brought in. If you are struggling with this, please contact our safety consultancy team. We can help you through this process and provide you with an induction program, as well as bespoke documentation for your organization.

Some considerations to think about include:

- Training your workforce in good hygiene practices and reinforcing these messages with posters, emails, and screensavers

- Strengthening the message that if you have any COVID-19 symptoms (prolonged cough and fever) or have been near people who have these symptoms to stay at home

- Communicating and reinforce your procedures and policies to your workforce through e-learning or alternative communication mediums

- Leading by example

We can also, where possible, work from home instead of working in an office. Some jobs are more suitable for this; but, it might be that some work tasks can be done at home, allowing staff to stay at home more often and only going into the workplace when necessary.

At the end of stage 4, we have now somewhat minimized the risk of exposure. But, what about those workers who come into contact with lots of people, such as public transport or frontline work – where the viral load (how much virus is around) is higher than you would expect in a workplace?

Personal Protective Equipment (PPE) – Protect the (Individual) Employee

PPE is the final stage of the hierarchy of controls and is to be used when engineering or administrative controls are not feasible or effective to reduce the risks to acceptable levels.

What is PPE?

PPE stands for Personal Protective Equipment. Its purpose is to protect an individual worker from the hazard – imposing a barrier between the wearer/user and the working environment.

PPE can create additional stress on the user. It can impair the ability to carry out their work and can create significant levels of discomfort – which is one of the reasons that PPE is the final stage of the hierarchy of control.

Examples of PPE are:

- Gloves (to protect the hands)

- Gowns, coats or aprons (to protect the body and clothing)

- Goggles and safety glasses (to protect the eyes)

- Masks, (to protect your respiratory system from what you breathe in) – these are known as RPE (Respiratory Protective Equipment).

There are numerous different types of masks (RPE) available, each of the different types have a different level of protection, depending on the hazard.

RPE is available in different sizes to allow for the facial differences of workers. Gender, ethnicity, build, and many other factors. This means that one size will not fit everyone; RPE needs to match the specific requirements of the worker.

If you are required to wear a mask for work purposes, such as asbestos removal or you are a healthcare worker, these masks should be appropriate for the work. This means that the mask is fitted to your face and it has been tested (using smells) to ensure that the seal around the mouth and nose is airtight.

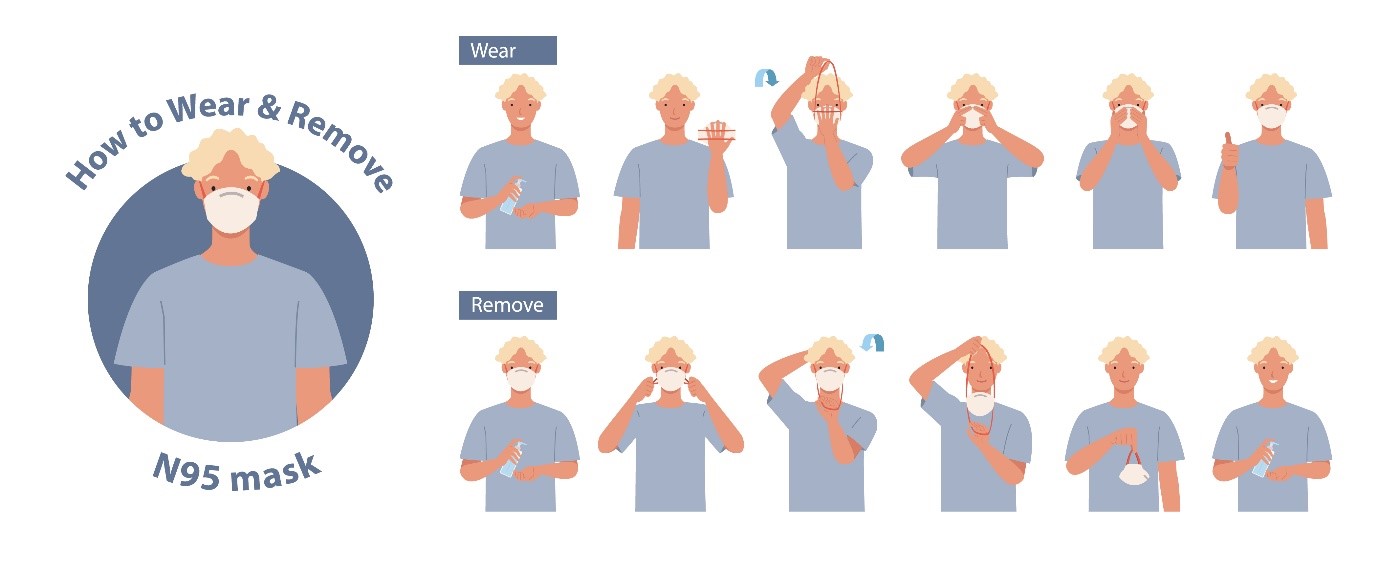

How to Wear and Remove Your FFP2-type (N95) Mask

In a situation where the mask is not for direct exposure to substances but to minimize the risk of transmission of COVID-19 virus, masks should be face-fitted. If it is not going to be possible, then you should follow this guide for using an FFP2-type (N95 mask). For example, on public transport, where there are lots of people and there is potential to have a high viral load.